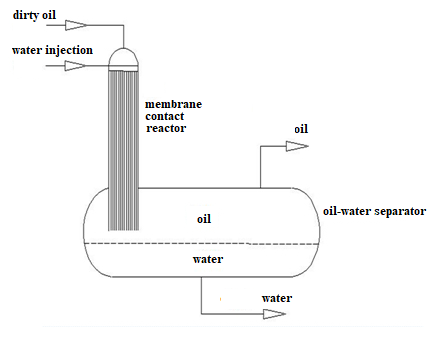

Basic principle:

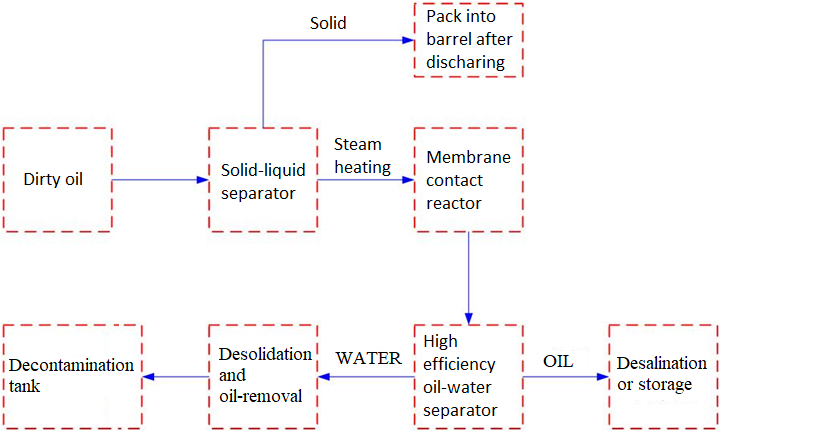

This core technology of self-developed membrane contact reactor and high-efficiency oil-water separator, combined with supporting additives, enables dirty oil and water injection in the membrane contactor fully and efficiently mass transfer, and break the stable oil-water solid three-phase wrapped structure and interacting chemical bonds, realizing high-efficiency separation of oil, water and solid and clean recovery of dirty oil.

Process flow

Characteristics

High efficiency

High-efficiency cleaning with patented technology, the dirty oil can be directly refined after purification treatment.

2.Environmental protected

The separated water has low oil content and COD, and the sewage treatment is simple.

3. Safe

The process conditions are easy to get, the plant runs safely and smoothly, and the slop oil dehydration and desolidification effect is good.

4. Technical indicators

The water content in the oil is ≤1%, the solid content in the oil is ≤0.5%, and the oil content in the external drainage is ≤200 mg/L.

Application

1. Oily sewage generated during production operations such as electric desalination and drainage of oil products tank farms, shutdown of equipment and equipment for purging, and slop oil recovered through oil separation and flotation processes;

2. The dirty oil produced by cleaning of various oil tanks;

3. Slop oil, floor oil, aging oil, etc. from treatment of oily sewage in oil fields.

CopyRight @ 2021, All Rights Reserved by Shandong Dream Clean Tech Co., Ltd

Technical Supports:KASON