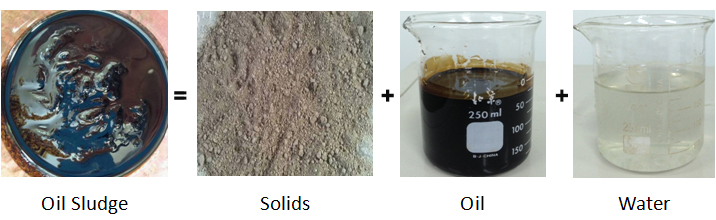

A large amount of sludge will be produced during the treatment of oily wastewater in the petrochemical industry, including:

l Pool bottom mud (grease trap, homogeneous tank, tank bottom pool, etc.)

l Oil-containing scum produced by air flotation process

l Excess activated sludge produced by biochemical process

Oil sludge contains water, suspended solids, oil, toxic and hazardous substances such as benzene series and phenols, it has been listed as hazardous solid waste by government.

Our oil sludge reduction dehydration drying treatment technology can process oil sludge from refineries at low operating cost and meet drainage waste water standard.

I. Technical Brief

Our oil sludge treatment technology includes sludge modification, high-efficiency dehydration,drying and burning as mixed fuel for CBF boiler.

Its main advantages are:

l Processing cost of one ton of oil sludge is just around 10 USD.

l The water content of the separated solids is less than 30%,its calorific value is similar to and can mixed with standard coal

l The whole process of sludge treatment like sludge dehydration, sludge drying and incineration, liquid removal treatment and sludge transportation are all carried out inside the refinery safely and environmental friendly

l The dehydration unit are also applied for bottom sludge and oily scum with high oil content besides biochemical sludge. Its featured with wide application,obvious reduction efficiency and low failure rate.

II. Oil Sludge Treatment Plant

Our integreated oil slduge treatment plant is modular which can be skid-mouted or fixed. It mainly consists of hydration unit, conveying system, drying unit, waste gas treatment unit and PLC control unit.

l high processing efficiency, small footprint, and is easy to disassemble, transport, and install.

l All motors of the equipment are of the highest level of explosion-proof, explosion-proof level DIIBT4.

l PLC programming and touch screen centralized control, the control cabinet is nitrogen positive pressure explosion-proof.

l The internal cavity of the equipment is equipped with nitrogen protection plus steam double insurance measures

l The chamber pressure transmission of the drying device detects the negative pressure of the inner chamber at any time to control the air flow in and out

III Effect after Treatment

With our company's technology and special equipment, the oil is through sludge reduction, resource utilization, and harmless treatment. The water content of solid waste is reduced from 95% to less than 30%, and the reduction rate is >90%. The separated oil can be recycled. After processing, the separated sewage meets the requirements for entering the sewage plant.

The whole sludge dehydration, degreasing and drying process is safe and environmentally friendly, without secondary pollution.

Inspection indicators of each material after processing

Separated material | Test Item | Test Result | Note |

Solid (sand & earth) | Water content | Less than 40% | Reduced by over 70% |

Water | Suspended matter | No more than 200 mg/L | Suitable for waste water treatment plant |

Oil content | No more than 1000 mg/L | ||

Oil | Water content | Less 1% | Suitable for refinery |

CopyRight @ 2021, All Rights Reserved by Shandong Dream Clean Tech Co., Ltd

Technical Supports:KASON